Roofing is a critical component of any structure, providing the necessary protection against environmental elements. Among the various roofing materials available, Bitumen Felt stands out due to its unique characteristics and benefits. This comprehensive guide aims to delve into the world of Bitumen Felt roof covering, from its historical roots to its modern-day application.

Bitumen Felt, often referred to as asphalt felt, is a roof covering material that has been used for over a century. It comprises a base, usually made from natural or synthetic fibres, saturated with bitumen, a viscous black mixture of hydrocarbons obtained naturally or as a residue from petroleum distillation.

The use of Bitumen for waterproofing purposes dates back to ancient times, but its application in roofing began in the 19th century. Over the years, Bitumen Felt roofing has evolved, with advancements in technology improving its quality, durability, and ease of installation.

One of the prime benefits of Bitumen Felt roofing is its durability. When installed correctly, it can last for many years, providing reliable protection against harsh weather conditions like rain, snow, and extreme temperatures.

The waterproofing capability of Bitumen Felt is unparalleled. Its composition makes it an excellent barrier against water ingress, keeping the interior dry even during heavy rainfalls.

Bitumen Felt roofing is relatively easy to install compared to other roofing materials. The process is straightforward, and with the right tools and expertise, installation can be completed within a short time.

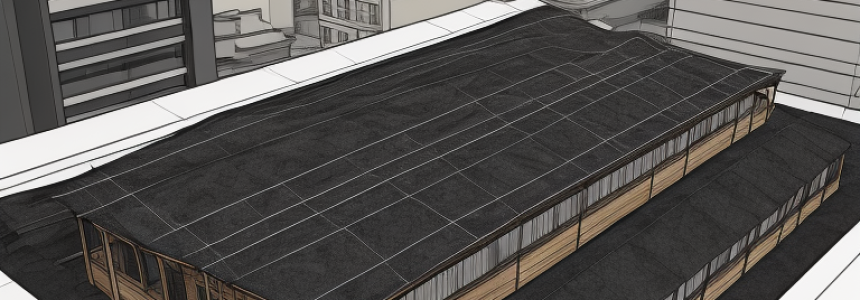

Torch-on felt roofing is a popular method where the bitumen felt is applied using a torch to heat the material and adhere it to the roof surface. This method provides a robust and durable covering, making it a preferred choice for many roofing projects.

Self-adhesive felt roofing is a modern alternative to the traditional torch-on method. This type of roofing comes with a pre-applied adhesive backing, eliminating the need for a torch during installation. It’s a safer and quicker method, making it a suitable option for DIY enthusiasts.

The first step in the installation process is preparing the roof surface. It’s crucial to clean the area, removing any debris, old roofing material, and ensuring the surface is dry. Any necessary repairs should be made to ensure a solid foundation for the bitumen felt.

Once the roof surface is prepared, the bitumen felt is rolled out and applied. For torch-on applications, the felt is heated as it’s rolled out to adhere to the roof surface. For self-adhesive applications, the backing is removed, and the felt is pressed firmly onto the surface.

After the felt has been applied, it’s crucial to seal the edges to prevent water ingress and ensure a watertight seal. This can be done using bitumen adhesive or by torching the edges, depending on the method of application.

Regular inspections are essential to maintain the integrity of a bitumen felt roof. Check for signs of wear, damage, and any loose or lifted edges that could allow water to penetrate.

If any damages are found during inspection, prompt repairs are crucial. Small holes or tears can be repaired with bitumen patching compounds, while larger damages may require the replacement of the affected area of felt.

The initial cost of bitumen felt roofing is relatively low compared to other roofing materials. The cost will vary depending on the type of bitumen felt selected and the size of the roofing area.

Maintenance costs for bitumen felt roofing are generally low. Regular inspections and prompt repairs can prevent larger issues and associated costs in the long run.

Bitumen felt is recyclable, which reduces the environmental impact when it’s time to replace or dispose of the roofing material.

Bitumen felt roofing can contribute to energy efficiency by reflecting solar heat, which can help maintain a cooler interior during hot weather.

Bitumen Felt Roof Covering is a reliable, cost-effective solution for anyone looking to replace or install a new roof. Its proven track record for durability and waterproofing, along with the ease of installation and maintenance, makes it a viable choice for both residential and commercial structures.